National unified service hotline:0757-26616782

中文National unified service hotline:0757-26616782

中文Please enter keywords for search

Foshan Zhongshun Water Treatment Technology Co., Ltd

Tel: 0757-26616782 26628076

Email: sdzs@sinozs.com

Website: www.sinozs.com

Official account: zs water

Address: No. 3 East Hongye Road, Ronggui Rongqi Avenue, Shunde District, Foshan City, Guangdong Province

Purpose:

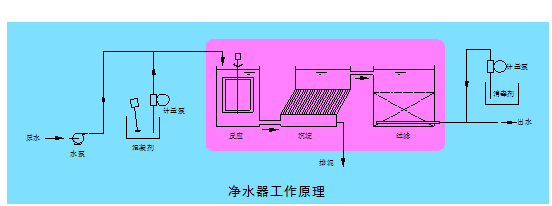

The pressure type Water filter centralizes the coagulant dosing, reaction, sedimentation, filtration and other treatment equipment in water purification treatment into a steel container, which is used to directly purify turbid water such as river water, reservoir water, well water, etc. into clean water. After disinfection treatment, the effluent can be used for drinking water. This equipment can be used for water supply treatment in domestic water, factory production water, field operations, military camps, construction sites, remote areas, islands, and tourist attractions, as well as for the discharge and reuse of industrial and domestic wastewater. Loading equipment onto cars can also be used for mobile water supply and emergency water supply in disaster areas.

Advantages:

● The pressure type Water filter integrates a variety of treatment equipment such as metering pump dosing, mechanical agitation reaction, high-efficiency inclined tube sedimentation and multi-layer media filtration. The treatment process is mature, the raw water quality has a wide range of adaptation, and the effluent quality is stable.

● The operation and management are simple, and operators can operate and use correctly after simple training.

● The equipment adopts factory specialized production and processing, with compact dimensions and convenient construction. The user only needs to provide a simple and flat site for installation and use. The installation location of the equipment can even be selected to be lower than the ground level.

● Pressure type water outlet, with a working pressure of up to 0.6MPa, can be directly sent to a high-level water tank or to a water consuming point for use, or can be connected to the original pipeline network for use. In the water supply system, there is no need to set up an intermediate pool or pump, which greatly reduces the construction and operation costs of the water supply system.

● Various automatic control devices can be installed on the equipment to easily achieve various automated operation control functions, such as setting the proportion of coagulants and disinfectants, automatic sludge discharge, automatic backwashing of filter pressure difference control, and variable frequency constant pressure water supply.

● The device has portability and can be easily disassembled, installed, and used in different places, and can even be installed on the vehicle for mobile use.

Main technical parameters:

Applicable raw water: surface water and groundwater such as river water, reservoir water, well water, etc.

Applicable raw water quality: turbidity ≤ 1000NTU, chromaticity ≤ 20 degrees, pH value 6.5-9.5, total iron ≤ 0.5mg/L, manganese ≤ 0.3mg/L, chloride ion ≤ 300mg/L, sulfate ≤ 300mg/L.

Raw water temperature: 5-40 ℃.

Working pressure: ≤ 0.6MPa.

Maximum resistance: ≤ 0.15MPa.

Effluent quality: In accordance with the GB5749-2006 Sanitary Standard for Drinking Water, with turbidity ≤ 3NTU. When combined with water disinfection treatment, the total number of bacterial colonies should be ≤ 100CFU/mL.

Specifications | Water treatment capacitym3/h | work voltage | power Kw | Operating weightt | Filling amount of filter material t | Recoil flow ratem3/h | Recoil water consumptionm3 |

JSYP-10 | 10 | 380V | 0.25 | 5.6 | 1.5 | 43~54 | 4~6 |

JSYP-20 | 20 | 0.75 | 14 | 3 | 86~108 | 8~13 | |

JSYP-30 | 30 | 0.75 | 20.5 | 4.5 | 130~162 | 11~19 | |

JSYP-50 | 50 | 0.75 | 40 | 9 | 216~270 | 19~32 | |

JSYP-60 | 60 | 0.75 | 47 | 10.5 | 259~324 | 23~38 | |

JSYP-80 | 80 | 1.5 | 75 | 15 | 346~432 | 30~50 | |

JSYP-100 | 100 | 1.5 | 92 | 18.5 | 432~540 | 38~63 | |

JSYP-125 | 125 | 1.5 | 120 | 24 | 540~675 | 47~75 |

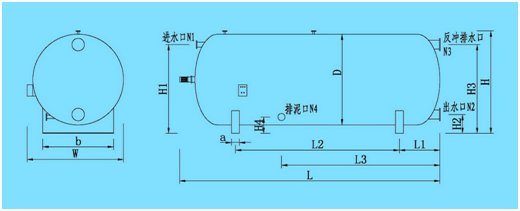

Specifications | L | L1 | L2 | L3 | H | H1 | H2 | H3 | H4 | D | W | a | b | N1 | N2,N3 | N4 |

JSYP-10 | 2315 | 550 | 900 | 1150 | 1950 | 1680 | 370 | 1680 | 350 | 1600 | 1800 | 200 | 1120 | DN65 | DN100 | DN50 |

JSYP-20 | 3450 | 800 | 1250 | 1800 | 2400 | 2050 | 415 | 2050 | 425 | 2000 | 2200 | 220 | 1420 | DN80 | DN150 | DN65 |

JSYP-30 | 4760 | 830 | 2540 | 2600 | 2400 | 2050 | 415 | 2050 | 425 | 2000 | 2200 | 220 | 1420 | DN100 | DN200 | DN80 |

JSYP-50 | 6340 | 960 | 3880 | 3600 | 2800 | 2470 | 510 | 2470 | 460 | 2400 | 2430 | 240 | 1720 | DN125 | DN250 | DN80 |

JSYP-60 | 7450 | 960 | 4920 | 4300 | 2800 | 2470 | 510 | 2470 | 460 | 2400 | 2430 | 240 | 1720 | DN125 | DN250 | DN80 |

JSYP-80 | 8050 | 1290 | 4780 | 4600 | 3450 | 3070 | 625 | 3070 | 580 | 3000 | 3250 | 360 | 2180 | DN150 | DN300 | DN100 |

JSYP-100 | 9800 | 1290 | 6530 | 5700 | 3450 | 3070 | 625 | 3070 | 580 | 3000 | 3250 | 360 | 2180 | DN200 | DN300 | DN125 |

JSYP-125 | 11350 | 1340 | 7950 | 6700 | 3650 | 3260 | 645 | 3260 | 580 | 3200 | 3450 | 360 | 2340 | DN200 | DN350 | DN150 |